When managing a factory, factory floor maintenance is critical for safety, productivity, and longevity. Keeping the floor in optimal condition not only enhances the appearance but also reduces the risk of accidents and extends the life of the flooring material. Implementing a comprehensive maintenance plan is essential, especially for industrial settings in Wisconsin, where harsh weather can pose additional challenges.

Conducting thorough floor assessments is the first step in maintaining a factory floor. Regular evaluations help identify existing issues that may affect the flooring's functionality. Assessments typically include checks for cracks, wear patterns, and moisture levels, which can lead to further complications if left unaddressed.

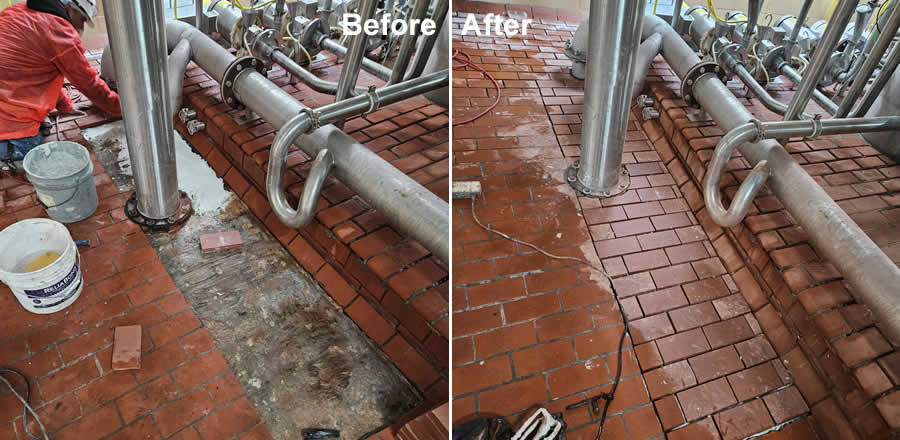

After an assessment, it's vital to diagnose the specific problems affecting your factory floor. By hiring experienced professionals, you can receive accurate diagnoses and effective repair solutions tailored to your specific flooring type, be it concrete, acid-resistant bricks, or epoxy systems.

Taking timely action prevents minor issues from escalating into costly repairs, ensuring operations run smoothly.

Understanding the variety of flooring options available is essential for making informed decisions about factory floor maintenance. Below, we explore some common types utilized in industrial settings:

Industrial bricks offer durability and resistance to the rigorous demands of a factory environment. Regular maintenance involves inspecting for loose bricks, ensuring proper sealing, and addressing any discoloration caused by spills or chemical exposure. Keeping bricks intact helps in maintaining a safe working environment.

Epoxy grout is often used in areas subject to heavy foot traffic and chemical spills. Its non-porous nature makes it an ideal choice for cleanliness. However, regular maintenance is necessary to check for cracks and ensure that it remains firmly adhered to the flooring material. Resealing may also be required based on usage levels.

Vitrified tiles are increasingly popular in industrial settings due to their water resistance and strength. When properly maintained, they can retain their appearance for years. Regular inspections should target:

Fully vitrified tiles offer an additional layer of durability, making them suitable for environments with extreme conditions. Regular cleaning and addressing wear promptly will help keep your tiles in excellent condition.

Acid brick is designed to withstand corrosive chemicals, making it ideal for facilities involved in the processing of harsh substances. To maximize their lifespan, the maintenance should focus on removing buildup and checking for surface integrity.

Acid-resistant bricks call for similar attention, ensuring that any acid exposure doesn't compromise their effectiveness. Regular cleaning with appropriate non-corrosive cleaners is advisable, and any damaged sections should be repaired quickly.

Factory floor maintenance refers to the routine tasks and procedures aimed at preserving, repairing, and enhancing the condition of the flooring used in manufacturing or industrial environments. It includes regular assessments, cleaning, repairs, and preventive measures to ensure safety and longevity.

Maintaining the factory floor is crucial for several reasons:

Regular assessments of factory floors are recommended at least twice a year. However, the frequency may increase depending on the level of activity, type of flooring, and exposure to harmful chemicals or spills. More frequent assessments can help catch issues before they escalate.

Different flooring materials call for distinct maintenance strategies:

Handling repairs involves several steps:

Effective cleaning helps prolong the life of factory floors. Here are some best practices:

Absolutely. By implementing a thorough maintenance schedule, facilities can anticipate and address issues before they disrupt operations. This proactive approach minimizes unplanned downtimes caused by accidents or repairs.

Using high-quality materials is essential for effective maintenance. Recommended materials include:

Creating a factory floor maintenance plan begins with:

By prioritizing factory floor maintenance, you create a safer, more efficient working environment conducive to productivity. If you have more questions or need practical solutions, reach out to BYCO One for expert advice and services tailored to your specific needs.

BYCO offers factory floor maintenance services throughout much of Southern Wisconsin. Some of our projects include the cities of Appleton, Beaver Dam, Columbus, Fond Du Lac, Madison, Menomonee Falls, Milwaukee, Monroe, Muskego, Oconomowoc, Oshkosh, Watertown, Waukesha, Waupun, West Bend, and surrounding areas in Wisconsin.

Implementing a successful maintenance program involves considering various elements unique to your factory environment. Here are key tips for effective factory floor care:

Investing in a proper factory floor maintenance program will not only enhance the aesthetic appeal of your facility but will also improve safety and productivity. By prioritizing routine assessments, targeted repairs, and appropriate maintenance for various flooring types such as industrial bricks, epoxy grout, and vitrified tile, your Wisconsin-based factory will thrive.

Ready to elevate your factory floor maintenance? Contact BYCO One today for tailored solutions that keep your operations safe and efficient!

© Copyright BYCO One. All Rights Reserved. Website Design.

Contact Information: